- Welcome to 60k House

- The first party on the site – 2009. [Photo credit: Kate Lilley]

- Light filters through smoke on the site

- Looking east – D’Entrecasteaux Channel and Bruny Island

- Looking west – heritage apple orchard and valley

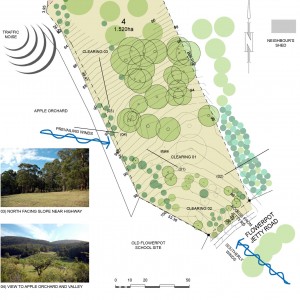

- Map Report

- Contour and detail survey

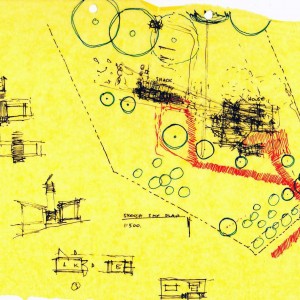

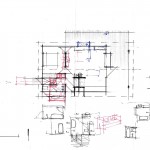

- Site Plan sketch – the first design sketch

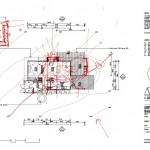

- Site Plan diagram

- Site analysis diagram

- Preparing the building site

- Leveling the building site

- Removing the topsoil to form the driveway

- The excavator track rolling the gravel on the driveway

- A truck delivering a load of gravel

- The first delivery truck – structural steel for the footings and slab

- The first concrete truck. They look heavy – they are

- Working within the lines – Alan digging the footings under the watchful eye of Greg

- Digging the strip footing

- The strip footings dug with trestle on the left for the string line

- Using the auger to bore the piers beneath the strip footing

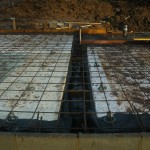

- The footings all dug with the trench mesh (steel reinforcing) in place

- The bored pier beneath the strip footing. The line of spray paint is to show where the pier is once the footing is filled with concrete

- The pump truck and concrete truck on the freshly made driveway

- The first concrete is pumped into the footing

- The stressful moment when the concrete pump gets blocked. The thing on the tripod is called a ‘dumpy’ and is used for getting levels on site

- Pumping the concrete into the footings

- My neighbour Josh pushing the steel reinforcing into the bored pier so it is tied to the strip footing

- The blockwork finished

- Setting up

- Equipment and materials for mixing the mortar: sand, water, cement, mixer, generator (power)

- The first block!

- Cutting blocks

- Scott laying the top course of blocks

- Trent ‘pointing’ the blocks (finishing off the joints)

- A beautiful straight, level blockwork wall

- The finished blockwork

- The invoice…

- Wash up after the blockwork has been filled with concrete

- Greg filling the blocks with concrete

- The top course of ‘knock out’ blocks, with the corner block already knocked off

- Preparing to fill: bailing out the water, removing the topsoil and knocking out the knock-out blocks

- Luke on the ‘whacker-packer’, compacting the gravel fill

- The ‘whacker packer’ sits silent as the sand waits to be spread across the FCR

- Forming the concrete strip thickening in the middle of the slab

- Digging the trench for the plumbing

- Is that a smile? First piece of floor insulation in place

- Delivery of sand – the top layer of fill

- Pete moving the sub-slab insulation into place

- Hint of a rainbow: working through the bad weather

- The polystyrene sub-slab insulation can be cut with a handsaw

- Steve and Greg laying the plastic sheet for the concrete to be poured over; Pete using the wheelbarrows as a makeshift sawhorse

- If you want a rainbow you have to put up with the rain: working through the bad weather

- Iron Man! Pete bending the steel reinforcing from the footings back so it can be tied into the slab

- The steel reinforcing in place and straight edge formed for the concrete slab to be poured

- The edge thickening in the slab, lined with plastic

- Steve tying the sheets of reinforcing together; the set down in the slab for the wet area

- Finishing off before the sun goes down

- Early start: stuck behind the first concrete truck while driving to site before sunrise

- More trucks: pumping the concrete to the slab via a pump truck

- Early morning sun: the concrete pour part way through

- Messy work: gumboots are a must

- The morning of pouring the slab: one concrete truck waits for the other to leave

- Pumping, leveling and vibrating the concrete

- Teamwork: Stuart screeds the concrete while Greg removes the excess

- Hands and knees: Stuart working by hand to make the fall to the floor waste (shower) in the wet area

- Flying solo: Stuart pilots the ‘helicopter’ – a mechanical tool for finishing concrete slabs

- Mind the step: the setdown in the slab for the wet area

- A thing of beauty: the slab, poured and nearly finished

- The view of Wineglass Bay from the top of Mt Amos

- Dean fixing the discs to the grinder

- Slow going: working around the slab

- The hire generator (power supply) for the concrete grinder

- Easy access: grinding the edge of the slab

- Collecting water from the dam for the concrete grinder

- Scrape it off: removing the paste made from the water and concrete dust

- Getting there: revealing the concrete finish beneath the sludge

- Looks more impressive when wet

- The (nearly) finished product: the salt and pepper look

- 60k House under construction

- Design inspiration: stacked apple crates at nearby Trial Bay Orchards

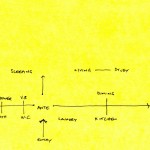

- Function and relationship diagram of 60k House

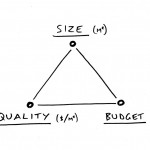

- Simple diagram – complex balancing act

- Apple crates: design inspiration for the cladding to reference the local fruit industry

- Colour inspiration from the bark of trees on site

- Going up: the first wall frame up in place

- Drop-saw setup ready to cut the studs to length

- Kapow! Greg using the nail gun to assemble the wall

- There was still no power connection so we used two generators for all of the power tools and air compressor to power the nail gun

- Down the bottom: damp course and metal strapping

- Smiles all round! The first wall is lifted into place

- Drilling a hole through the bottom plate for a Dynabolt to be driven into and tightened, locking the wall to the slab

- The first wall up, standing on its own (with the help of some temporary bracing)

- The second wall nearly ready to lift into place

- Squaring off the end wall with temporary bracing

- Taking shape: with more walls up it’s beginning to look like a building

- Nailed it: Pete nailing the brace ply to the corners of the wall

- Really taking shape! The first truss in place – helps make the overall shape look less like a Quaker barn

- Walls up, brace ply on, trusses up and purlins on

- A well earned thirst: after three solid days the walls were up and the roof trusses were on

- Taking shape: the roof trusses and framing in place

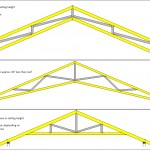

- Various truss options for a higher ceiling: 60k House has type 3

- Waiting for a lift: truss ready to be lifted into place

- The roof truss and bracing plan, nailed to a wall for easy reference

- Attaching the purlins

- The trusses are tied down to the top plate of the wall with metal strap bracing

- Roof trusses and bracing in place

- The ends of the trusses will be taper cut to reduce exposure of the end grain to the weather

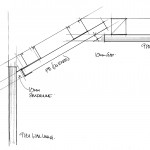

- Working things out: drawing a 1:1 detail of the fascia

- Greg fixing the fascia to the purlin

- Trusses up and most purlins in place

- Installing the gutter brackets

- Sisalation installed under the roof sheeting

- First sheet of roofing up!

- Ian trimming the sheets of polycarb before installation

- Selected for performance: the ‘Opal’ colour polycarb provides diffuse light while reducing heat transmission and cuts out UV

- The ends of the purlins are taper cut to reduce exposure to the weather. The end grain is also oiled to minimise weathering and water penetration

- Out in the open: the range of colours supplied, laid out on the grass

- Fade to white: the gradation of the multi-coloured roof

- End of roofing day 1: half of the roof in place

- This is known as ‘weathering’ and prevents water being blown up the valley beneath the ridge capping

- Finishing off: forming the end of the ridge capping

- Sense of enclosure: the roof on

- Looking over the roof to the apple orchard and valley beyond

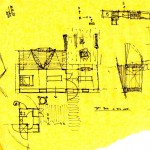

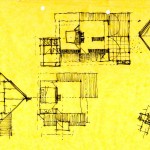

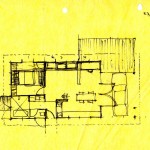

- Just build a big roof: an early design sketch showing semi-permanent camping with hammocks, fire pit and outside toilet

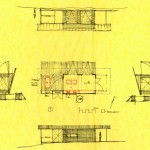

- Break-through: after deciding to apply for the FHBB this layout incorporates all of the functions under the one roof

- Fresh eyes: more ideas and suggestions from a colleague

- Looking at a squarer footprint, internal thermal mass walls and the possibility of an upper level loft

- Drawing over the approved Development Application design

- Getting close: nearly the final design

- Close: this is very close to what is being built

- Figuring it out as we go: examining where the cement sheet cladding should sit in relation to the window frame

- Easier than doing it by hand: the excavator covering in the power cable

- Cover up: filling in the trench

- Unwinding the poly water pipe to lay in the trench with the warning tape

- All done: no pole, no overhead wires – underground power connection in place

- Within reach: the ‘upside-down’ meter box with the panels mounted at the bottom

- Cherry picker of a different variety: connecting the power cables at the top of the new pole on the corner of my block

- Adding the fittings to the water tank

- Easy does it: filling up the tank base

- Ag drain covered in geo-tech cloth to prevent it being

- Good timing: the tank arrived just as we finished leveling the tank base

- All wrapped up: the building covered in wall wrap and some of the high cladding

- Light and airy: plenty of ventilation beneath the gable (before it gets covered up)

- The large openings not wrapped

- Overlap: ensure the wrap laps over other sheets, and always the top layer over the bottom layer so water can run off

- Batten down the hatches: vertical timber battens to provide an air cavity and to fix the cement sheet to

- On the level: evening out the timber battens prior to fixing the cement sheet cladding

- Trimming the excess roofing sisalation

- Working it out: resolving the detail of where the face of the cladding will sit

- The first piece of cement sheet cladding being put up

- Neat detail: cement sheet cladding, flashing, window head

- Light and shade: the corner of the building in the afternoon sun

- Wind assisted: high winds ripped part of the wall wrap off the timber frame

- Second wall cladding on: the remainder of the solid wall will be timber weatherboards

- The cement sheet is easily cut with this hand tool

- Enclosure: inside the building feels very different with the wall wrap up

- Sitting pretty: covering in the septic tank

- Thar she flows: all of the plumbing coming out of the rear of the house

- Delivery service: the septic tank being moved off the truck

- Gone: the absorption trenches, covered in topsoil, hardly noticeable except for the inspection opening pipe

- Second time lucky: lowering the septic tank into the hole for the second time

- On the level: the first absorption trench following the contours of the site

- Even flow: the splitter box ensures even flow to each of the absorption trenches

- Location location: the hole for the septic tank

- Preliminary Bushfire Hazard Management Plan for 60k House

- Cause for concern: a large branch fallen from a stringy bark onsite

- Clean: the area to the south of the house cleared

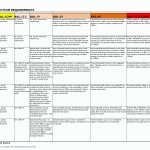

- Colour coded: a summary of the different requirements for each of the BAL ratings. [source: State Government Tas – Department of Justice]

- Open wide: all awning windows are fitted with metal mesh flyscreens to prevent embers entering the building

- Shade seekers: outside under the roof on Christmas Day

- Just in case: some more gravel for the driveway before the birthday party

- Primal: there’s something that draws people to fires

- Meat: the cornerstone of an Aussie BBQ, seen here stacked on a pile of recycled bricks

- Can’t have a gathering without a fire

- Four of a kind: tradies quenching a well-earned thirst

- Cool: setup for comfort on a scorcher summer day

- Human nature: in the heat, outside under the roof

- Welcome entry: Tas Oak timber floor boards supported on a timber frame

- Setdown: the timber frame for the floor

- Nailed it: nailing the floor boards in place

- Smooth operator: sanding the floor boards for a smoother finish

- Shiny and new: Greg applying the first coat of the wax

- A thousand cuts: cutting the ends of the floor boards to make way for a a bead of silicone where the two materials meet

- Assortment: second hand sheets of roofing used to enclose the building to protect the timber floor

- Room with a view: looking out above the temporary screen

- Right to the edge: Dean grinding the floor

- Sign of the times: home made sign indicates not to do the Tassie two-step dance on the wet floor

- Done: the finished polished concrete floor

- Pipes in the bathroom

- Run dem cables: Alan running the electrical cables through the wall

- A whole lotta love: some of the cables for the lights and power points in the kitchen

- Bend it like Beckham: Ian bending the copper pipe

- Easy to reach: Ian working on the shower taps

- Pride of place: the first item connected and installed in the house

- Best spot for a signal: installing the TV aerial

- Coming down: pulling the coaxial cable down from the aerial through the roof

- Straight ahead: pointing the aerial between the trees

- Playtime: Ian working on the laundry trough before installation

- Power it up: Alan installing a power point inside

- Quick and easy: temporary plumbing waste from the laundry trough

- The calm before the storm: the site the morning that construction began

- The plywood ceiling installed, with the electrical cables for the lights poking out

- A drawing! Working out the detail of the material junction between the ply wall lining, the plasterboard ceiling and the ply ceiling

- Pack it out: Greg nailing up timber battens to get the depth right for the shadow line between the different materials

- Greg fixing the furring channel for the plasterboard

- Packed to the rafters: the ceiling insulation held in place by the furring channel

- Stick it: applying the adhesive to stick the plasterboard to the metal furring

- Ready to go: insulation installed and adhesive in place – ready for a sheet of plaster

- As well as the adhesive the sheets of plaster are also fixed with screws, which are then plastered over for a smooth finish

- Demonstration: Greg plastering the first join – it was the only plastering he did…

- Straight cut: Greg cutting an edge of sheet with a hand saw

- Plane sailing: Greg using a hand plane to aris the edges of the plywood sheets to conceal any inconsistencies along the edges

- More battens: Greg fixing the ceiling battens to hold the flat plywood ceiling

- Getting there: half of the ceiling insulation installed and the battens for the plywood ceiling

- Filling up: the ply sheets cover a lot of area – a large part of the ceiling was done quickly

- Gun control: Greg using the nail gun to fix the plywood sheets in place

- Little ray of light: the reflected sunlight on the ply ceiling

- Done: the ceiling in place, just needing a sand and some paint

- Nearly done: lining the end wall of the bedroom

- Line ’em up: the wall batts fitted in between the timber studs

- Caution: take care when cutting batts around electrical wires

- Poker: stuffing the batts in between the stud and window frame

- Jammed tight: batts cut to size

- Made by hand: Greg arised each edge of the ply sheet with a hand plane

- Lining up: the stacked apple crate reference extends inside to the sheets of ply

- All over: batts packed around plumbing pipes and electrical wires

- Contrast: the black kitchen and light ply walls

- Fun for the whole family: a blackboard splash back can be useful for lists and creative pursuits

- Ebony and ivory: the two toned wall to the kitchen

- Complete: an entire wall lined

- Kitchen installed: the joinery units fixed in place

- Food store corner: the fridge and pantry will go in the corner; the stove in the gap between the units

- Working drawing: a quick sketch of the kitchen joinery construction

- Kitchen delivery: the joinery units being unloaded from the back of Greg’s ute

- Kit of parts: the kitchen units and the tops, ready for assembly

- On the level: Mark leveling the kitchen units. He said the floor was one of the flattest he had ever seen

- Exposed: the edges of the plywood left untreated

- Gunning it: Mark caulking the joins in the bench tops

- Used kitchen: the aftermath of Xmas

- Attention to detail: the black sealant between the joins in the bench tops and around the flush edges of the sink and trough

- Temp job: the waste outlet from the laundry

Pingback: Leverage

Pingback: Multiple streams of income

Pingback: Investing in the stock market